British scientist Michael Faraday created the first electromagnetic generator (Faraday disc) in 1831. It is known as a DC generator, an electrical generator that generates electrical energy. This device’s primary function is to transform mechanical energy into electrical energy. All of the electrical power grids are fed by the generator.

An electric motor can operate the generator’s reverse function. The motor’s primary job is to turn electrical energy into mechanical energy. Both engines and generators share similar characteristics. The overview of DC generators is covered in this article.

What is a DC Generator?

A DC generator’s main job is to turn mechanical energy into electrical energy. The electromagnetic induction theory states that an emf will be produced following Faraday’s Laws when the conductor cuts the magnetic flux. When the conductor circuit is closed, this electromotive force might cause a current to flow.

Pole Core and Pole Shoes

The Pole Core and Pole Shoes are bolted or yoked to the magnetic frame. The poles are called salient poles because they are forced inward. There is a curved surface on each pole core. Typically, thin cast steel or wrought iron laminations are hydraulically pressed to create the pole core and shoes. The polar substance serves the following purposes:

- The magnetic flux more evenly overflows over the armature periphery while supporting the field or stimulating coils.

- It expands the magnetic circuit’s cross-sectional area, which lowers the magnetic path’s reluctance.

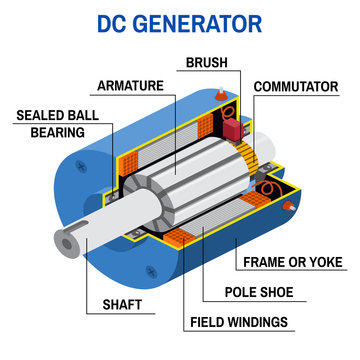

Construction Of A DC generator:

A DC generator can theoretically function as a DC motor without requiring structural modifications, and the reverse is also conceivable. Consequently, a DC machine can be broadly described as either a DC motor or a DC generator. These fundamental constructional aspects apply equally to the building of a DC motor. Therefore, rather than merely saying “building of a DC generator,” let’s refer to this step as “creation of a DC machine.”

1. Stator

The primary purpose of the stator, a crucial component of the DC generator, is to create the magnetic fields necessary for the coils to spin. These magnets are positioned such that they will fit in the rotor’s area.

2. Rotor or Armature Core

The second crucial component of the DC generator is the rotor, also known as the armature core. It is constructed of slotted iron laminations that are layered to create a cylindrical armature core. These laminations are typically provided to lessen eddy current-related loss.

3. Armature Windings

The armature core slots are responsible for holding the armature windings in place. These are wound in a closed circuit and connected in series and parallel to increase the total amount of current produced.

Read More: How To Measure For A Screen Door? What Are The Advantages And How We Can Replace Them?

4. Yoke

Yoke, the DC generator’s external frame, is constructed primarily of steel or cast iron. It provides the mechanical power required to convey the magnetic flux transmitted through the poles.

5. Poles And pole shoe

The field windings are primarily held in place by them. These windings are often wound on the poles, and the armature windings connect them in series, if not parallel. Additionally, welding rather than screws will allow the bars to hook up with the yoke.

6. Armature Winding

The conductors are appropriately linked and wrapped in bands made of steel wire looped around the body. Armature Winding is the name given to this configuration of conductors. The DC machine’s armature winding is its brain. Power conversion happens during the winding of an armature. Here, in the case of a DC generator, mechanical power is converted into electrical energy. The windings are divided into two categories based on connections: lap windings and wave windings.

7. Commutator

The commutator creates an electrical connection between the rotating armature coil and the stationary external circuit. It is simply a cylindrical construction made of wedge-shaped copper segments installed on the machine’s shaft and isolated from one another by mica sheets.

The commutator, a mechanical rectifier, transforms the alternating emf generated by the armature winding into a direct voltage across the brushes. The armature coil or winding ends are connected to various commutator segments.

8. Brushes

The purpose of the brush is to supply the external load circuit with the current drawn from the commutator. The meetings are produced in a range of compositions to meet commutation needs. It is rectangular and constructed of carbon, graphite metal, or copper. The brush holders, which are positioned on a rocker’s arm, are filled with brushes. The brushes are placed in the rocker’s arm to touch the commutator.

Adjustable springs are used to modify brush pressure. The friction caused by a high bush pressure causes the brushes and commutator to heat up.

9. Bearings and Shaft

Smaller DC generators employ ball bearings at both shaft ends, but more giant machines use roller bearings at the driving and non-driving end. The shaft is made of minimally alloyed mild steel. It is employed to move mechanical power away from or toward the engine. The commutator, cooling system, and armature core are some rotating parts that are mounted and keyed to the shaft.

Working principle of DC generator

A DC generator’s operation is based on Faraday’s electromagnetic induction law. A conductor experiences an electromotive force when it is situated in an unsteady magnetic field. The generator’s electromotive force equation can be used to calculate the size of the induced e.m.f.

The induced current will flow into the lane if the conductor is situated on the closed road. In this generator, the armature conductor will rotate in the electromagnetic field created by the field coil. Consequently, the armature conductor will produce an electromagnetically induced electromotive force (e.m.f.). The Fleming right-hand rule will provide the induced flow’s route.

Conclusion

Auxiliary power systems are not necessary for DC generators because the voltage output power is frequently sufficient to recharge a loaded battery. In reality, DC generators are commonly employed in off-grid circumstances where access to electric power is also a key consideration.

FAQs

AC converts mechanical energy into electrical power. The electromagnetic induction theory underlies its operation. When a coil rotates in a magnetic field, the direction of the induced current is determined by Fleming’s right-hand rule.

Field and armature winding are the two windings that make up a DC motor or machine. While the armature winding can rotate, the field winding is fixed.

The electromagnetic induction principle states that an EMF, or electromagnetic force, is induced in a conductor whenever a change in the magnetic flux is associated with that conductor.